Working with Christie’s D4K40-RGB

From the number of enclosure requests Tempest is seeing for Christie’s new flagship projector and its slightly less powerful cinema variants, it’s clear that the guys in Kitchener have a major success on their hands! In recent months Tempest has worked on projects for both indoor and outdoor enclosures for this machine, and we have learned a lot along the way…

Weighing in at 130kg (285lb) before you add a lens, this is a BIG projector! Fortunately for us, it comes with M12 threaded holes at each corner, and we found the best way to handle it was to attach a sling to lifting eyes screwed into those sockets and use a forklift – this is not something you want to drop on your toes!

Then there’s the airflow – unlike most projectors, the air inlet takes up most of the right side, and the exhaust is most of the back panel. We at Tempest have generally found that today’s laser-based projectors are more forgiving in terms of airflow than their lamp-based predecessors, with higher volumes of cooler, slower-moving air being easier to manage inside an enclosure, but this one has been tricky…

It’s a given that the lifetime of a laser light engine can be significantly reduced by running at high temperatures, and most projector manufacturers protect this by limiting light (and therefore heat) output when the projector sees its inlet temperature rising. The D4K40 is no exception, and although Christie publishes a 40°C (104°F) environmental limit, lumens reduce progressively when the inlet temperature – as measured by the projector’s sensor – exceeds 25°C (77°F). So, in an air-conditioned booth, the 13,650 BTU/h projector will hum along nicely at full brightness, but when you pack it into a box, maintaining that performance poses some real challenges. Since the light output is governed by the sensor buried just inside the top left corner of the inlet grille, the first order of business is to keep it happy! This is made harder by the fact that, when the three laser engines are running, this sensor consistently reports temperatures that are higher than the actual air temperature entering the grille, being influenced by radiated heat from inside the projector. This varies with actual conditions, but we have measured differences up to 7°C , so it can be significant. On top of that, in the tight confines of an enclosure the proximity of the exhaust panel, just around the back of the chassis from the inlet, poses a real risk of recirculating exhaust air into the inlets, potentially giving rise inside an enclosure to a thermal runaway condition.

There is another consideration here too, which is color balance; the three lasers (red, green and blue) all respond slightly differently to temperature changes, so it becomes important to maintain a reasonably constant operating temperature to maintain color balance calibration. Temperature swings, regardless ofdirection, can upset this balance, leading to undesirable color shift.

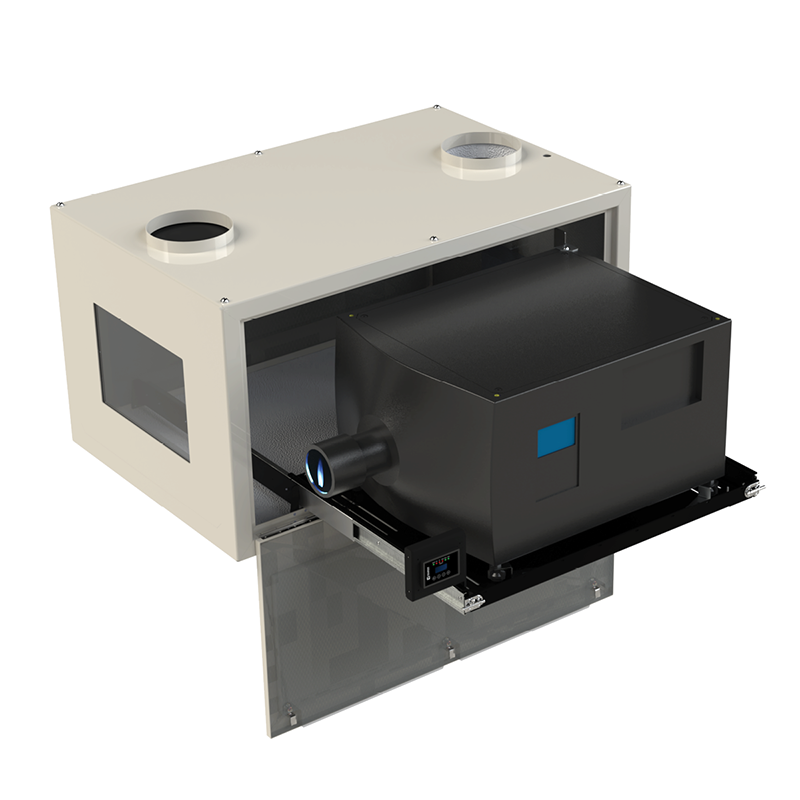

So there’s a lot to think about, and this is where a decade or more of hard-won experience in the thermal management of hot projectors in tight spaces turns out to be key. Following extensive trial-and-error testing at the Tempest factory near Los Angeles, we found that the way to keep the air inlet clear of recirculated exhaust air, and to keep the inlet sensor as close to actual air temperature as possible, was to design and mount a frame on the right side of the projector, with a pair of fans blowing into the inlet area, active whenever the projector light-engine is running (and we know this from the current sensor in the enclosure controller). The open frame touches the inside of the door insulation when the enclosure is closed, successfully isolating the inlet airflow from the exhaust grille on the back of the chassis. This frame mounts easily to two of those M12 sockets on the top of the chassis, leaving the removable top panel clear for service access.

With these issues addressed, we then needed to consider no fewer than six operational scenarios, for different Tempest enclosure families:

- Tacit –indoor HUSH enclosures, with ducted air inlet/exhaust and remote exhaust fan. Ourquietest indoor solution, in both landscape and portrait configurations

- Cyclone –outdoor enclosures, landscape and portrait, usually located in tourist destinations withwarm climates!

Tacit

Once we had designed the inlet fan box, we moved the inlet duct opening and inlet air filter from the front to be directly above the right side of the projector. So now the inlet air is pulled directly into the inlets and all is well. All is well that is, IF the inlet air is at a nice low temperature – say 20-22°C (68-72°F). We like to have that inlet air come from a neighboring air-conditioned room, which may or may not be feasible, depending on the building. Another option is to feed cooled air from the building’s HVAC system, but in many cases that becomes warm air in Winter, so not always realistic. Tempest offers AC Assist, a spot cooler that blows cooled air into the inlet duct, mixing with room-temperature air to achieve the desired blended inlet temperature. The cooler is controlled automatically by the DEC enclosure control system and runs only when the projector lasers are running.

Cyclone

There may be people out there making enclosures for tabletop projectors in cool countries, but at Tempest we never seem to get those jobs! Many of Tempest’s installations are in destinations such as Singapore, Dubai, or Florida – in other words HOT and HUMID, and frequently on the ocean, with highly saline air that likes nothing better than to corrode projector ballasts and all those plated steel parts… Welcome to our world!

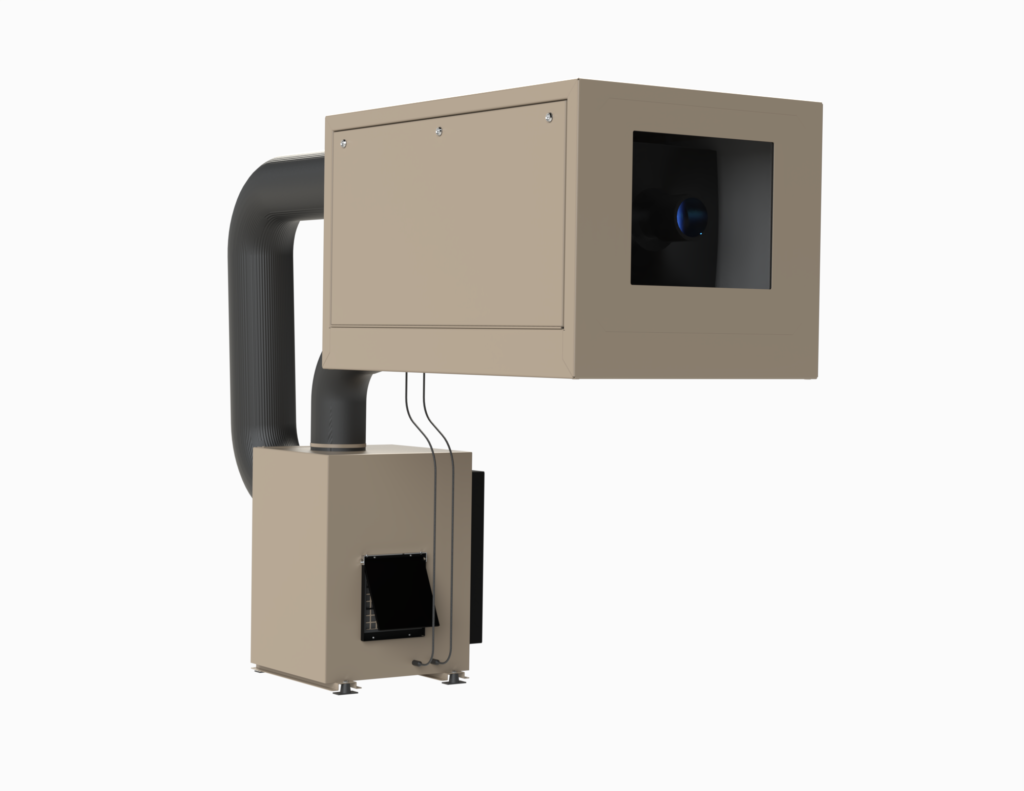

Although we have traditionally avoided the use of air conditioning, in this case it is unavoidable for many of the locations where Tempest customers operate. So, we partnered with a leading US-based cooling manufacturer to design a closed-circuit active cooling system specifically for large, temperature-sensitive projectors such as the D4K40. We call it Tempest ActiveCoolTM, and it will be shipping to customers from Spring 2020. ActiveCool is necessary when showtime temperatures above 22°C (72°F) are expected, and the full 40,000 ANSI lumens output is required. Our testing has shown constant projector inlet temperature of 22°C in a 40°C ambient, which is pretty extreme (even in places like Saudi Arabia, where daytime temps can exceed 50°C, things cool off significantly after sundown).

To eliminate the risk of vibration (a real problem for long projection throws – you do NOT want to mount an AC compressor in the same chassis as a projector), ActiveCool is a separate cooler, optionally available with an additional vibration-damping kit, that connects to the Cyclone enclosure using two flexible duct hoses – ideally no more than 2-3m (6-10ft) long. There is also a power cable that plug into the enclosure, making operation fully automatic. When the projector is running the system maintains a cooled airflow into the enclosure, at a constant temperature set by the user in the cooler control panel. Since this is a closed circuit, outside air is not used, further protecting the projector from harmful airborne pollutants such as salt or chlorine. A salt fog protection kit is available for the ActiveCool cooler, protecting the compressor components from airborne contaminants where necessary.

Portrait Applications

All the above refers to landscape orientation, but we are seeing more and more portrait enclosures called for, probably now about 20% of our enclosure output. Tempest offers portrait versions of all the above solutions, and in fact the cooling challenges are slightly easier to deal with in portrait enclosures. We designed a robust stainless steel portrait mount to handle the D4K40’s weight, and with some tilt adjustment to compensate for the reduced horizontal lens shift. Tempest’s portrait D4K40 enclosures generally bring inlet air in below the projector, blowing cool air into the projector intake from below – so the projector MUST be mounted right (air inlet) side down, connector panel up. In the case of Tacit, this means an internal duct is used to bring the inlet air from the top entry to the underside.

And going forward?

It seems clear that all the major projector manufacturers will continue to develop ever-brighter projectors, some of which will inevitably find their way into applications requiring enclosures of one kind or another. Tempest will continue to work with all our friends in the industry, investing time and expertise into the creation of innovative enclosure solutions that live up to our company’s motto –

Any Projector, Anywhere.

For product details, drawings and manuals, visit www.tempest.biz.

Sales enquiries: info@tempest.biz.